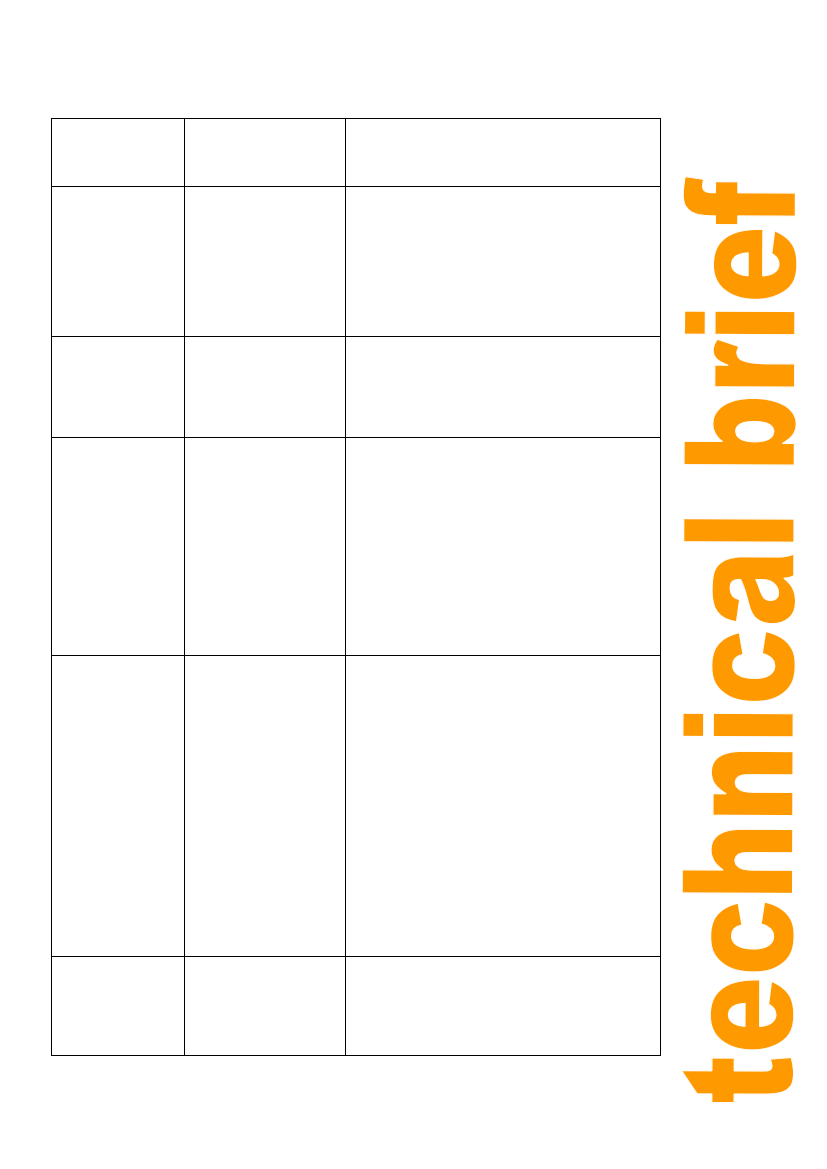

Gum sweets

Practical Action

Unpleasant

appearance

Varying shape of

gums

Sour or

unpleasant taste

Gums lack body

and shape.

Lumps of gelatin

Gum ageing

If receiving customer complaints, check

production dates. Ageing occurs due to the

evaporation of moisture.

Cold moulding starch The starch should be at 32 - 34°C.

Highly moist starch

Insufficient frosting

Gum ageing

It should have a 6-9% moisture level.

Check the frosting process.

Ascertain the production date.

Faulty oven

Monitor airflow within the oven.

Boards placed at the

hot air inlet.

Insufficiently mixed.

Lack of hygiene

Move the boards away from the hot air inlet.

Lengthen the mixing time.

Wash all equipment very thoroughly.

Poor quality gelatine

Use better quality gelatine.

Loss of flavour

Buy a sufficient quantity of flavourings to last at

least 3 months. Store in caramel bottles and

place in cupboards in a dry place. Ensure that

lids are firmly closed, and once opened use

within 24 hours.

Starch is contaminated Change the starch.

with alien flavours.

Add acid to a hot

gelatine solution.

Delay the addition of the acid until the last

possible moment, ensuring that it is thoroughly

mixed in.

The gelatine is curling Slowly add the gelatine to water at 88°C, stirring

up slowly.

The syrup has a high

temperature

Cool the syrup to 100°C before adding the

gelatine mix.

The gelatine has little

strength

Check the temperature.

Variations in pH level

Monitor the amounts of acid being added. Use

acid only to achieve pH 3.8 – 4.0.

Add 0.2% of a pH-regulating salt (eg. sodium

citrate) to avoid fluctuations in pH levels.

Slow-dissolving

gelatine.

Change gelatine type, or supplier.

Insufficient soaking of Soak in water for at least 20 minutes.

the gelatine.

3